In our quest for a sustainable future, the role of recycling in manufacturing industries has become increasingly paramount. Among these, steel recycling stands as a beacon, illustrating the potential of resource recovery in heavy industries. This process not only reduces the demand for raw materials but also minimizes the energy-intensive extraction processes.

As we delve into the world of steel recycling, we’ll explore the grades of steel, the intricacies of the steel manufacturing process, and the wide-ranging environmental benefits this practice brings. Join us as we pivot towards green manufacturing, proving that sustainability and industry can indeed go hand in hand.

Grades of Steel: The Building Blocks of a Sustainable Future

As one of the most versatile and widely used materials in modern society, steel comes in various forms and grades. These grades are classified based on their composition, properties, and intended use, making them essential building blocks for many industries. For recycling purposes, it’s important to note that not all steels are created equal. Some grades are easier to recycle than others, while some require specialized processes that can be costly and energy-intensive. Therefore, understanding the different grades of steel is crucial in maximizing the efficiency of the recycling process.

Basic Carbon Steels

Basic carbon steels make up a significant portion of the world’s steel production. They consist mainly of iron and carbon, with small amounts of other elements such as manganese, phosphorus, and sulfur. These steels are relatively easy to recycle, using traditional methods such as electric arc furnaces. Due to their high recyclability and versatility in applications, they play a crucial role in the circular economy.

Alloy Steels

As the name suggests, alloy steels are made by adding various alloying elements to basic carbon steels. These elements alter the properties of the steel, making it stronger, more resistant to corrosion, or heat-resistant. While they offer improved performance in applications, their complex composition makes them trickier to recycle. Specialized processes are required to extract these alloying elements, which can be energy-intensive and costly.

Stainless Steels

Stainless steels are a type of alloy steel that contains at least 10.5% chromium, making them highly resistant to corrosion. They also contain varying amounts of nickel, manganese, and other elements to enhance their properties. Due to their high resistance to corrosion and heat, they are widely used in industries such as construction, transportation, and food processing. However, the recycling process for stainless steel is more complex and energy-intensive compared to basic carbon steels.

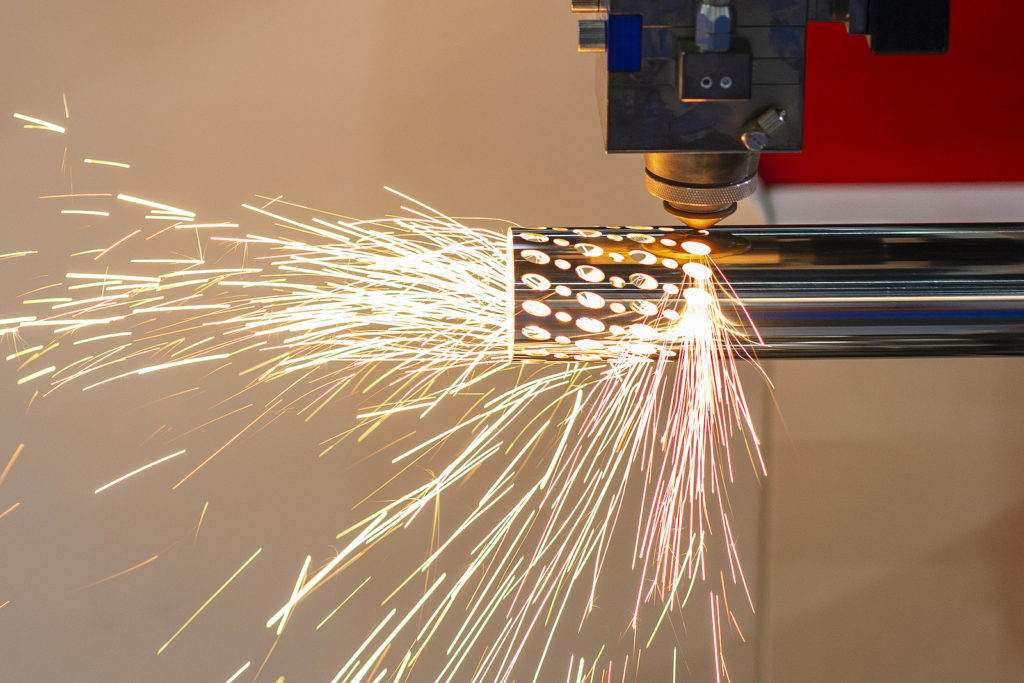

Steel Manufacturing: A Resource-Intensive Process

The production of steel involves high temperatures, large amounts of energy, and a variety of raw materials. The traditional method for manufacturing steel is through the blast furnace process, which uses iron ore, coal, and limestone as the main inputs. This process releases carbon dioxide and other greenhouse gases, making it a significant contributor to climate change.

However, with the advancements in technology and growing concerns for the environment, there has been a shift towards greener methods of steel production. Electric arc furnaces powered by renewable energy sources such as solar or wind are becoming more prevalent. These furnaces can recycle scrap steel and reduce the need for raw materials and energy.

Environmental Benefits of Recycling Scrap Steel

The benefits of steel recycling go beyond reducing the demand for raw materials and minimizing greenhouse gas emissions. It also saves water, reduces air pollution, and conserves energy. The World Steel Association reports that recycling just 1 ton of scrap steel can save 1.5 tons of iron ore, 0.5 tons of coal, and 0.3 tons of water. Additionally, recycling steel can save up to 75% of the energy required to produce it from raw materials.

Moreover, scrap steel recycling also helps in waste management by diverting scrap metal from landfills, reducing their environmental impact. It also creates job opportunities in the recycling industry and promotes a circular economy where resources are reused instead of discarded.

The Future of the Steel Recycling Industry

The demand for steel is expected to continue rising as economies grow and infrastructure development continues. Therefore, the need for sustainable practices in steel manufacturing and recycling will only become more crucial. With advancements in technology and a growing awareness of environmental issues, we can expect to see even more efficient and greener methods of steel production and recycling.

As we strive towards a sustainable future, steel recycling stands as a shining example of how industry and the environment can work together for the greater good. So, let’s continue to pivot towards green manufacturing, one recycled steel at a time.

Are you interested in recycling scrap steel to help support your local economy and boost your bank account? Contact Zore’s Recycling at 317-244-0700 to learn more about how our Indianapolis scrap metal recycling services can benefit your bank account. We also offer free junk car removal for those who wish to recycle a junk car. We pay cash on the spot for all metal scrap, including vehicles.

Related Posts:

Is Galvanized Steel Better Than Other Kinds of Structural Steel?

Is Aluminum Better Than Stainless Steel?

What is Tool Steel?