When you think of recycling, your mind probably goes to the usual suspects—plastic bottles, cardboard boxes, and aluminum cans. But did you know your backyard is home to a goldmine of recyclable metal items? From rusty lawn mowers to old patio furniture, many common backyard objects can be recycled at a metal recycling center. In this post, we’ll explore how Eco-conscious families and homeowners can make more space in their backyards and some fast cash at the same time, all by recycling metal!

Why Metal Recycling is Crucial for Eco-Conscious Families

Recycling metal isn’t just about clearing out your clutter; it’s a powerful way to contribute to environmental sustainability. Metals are infinitely recyclable, meaning they can be reused over and over without degrading their properties. This makes metal recycling a key player in reducing waste and conserving natural resources.

By recycling old backyard items, you’re not only keeping them out of landfills but also reducing the need for new raw materials. This translates to fewer mining activities, lower greenhouse gas emissions, and a significant reduction in energy use. For Eco-conscious families, metal recycling is an easy yet impactful way to live more sustainably.

Identifying Recyclable Metal in Your Backyard

Your backyard might seem like an unlikely place to find recyclable metal, but it’s often brimming with possibilities. Here are some common backyard items that can be taken to a metal recycling center:

Aluminum Patio Furniture

Aluminum patio furniture is a popular choice for outdoor decor due to its durability and resistance to rust. When these pieces start to wear out, don’t toss them in the trash. Aluminum is highly recyclable and can be turned into new products with minimal energy.

Cast Iron Furniture

Cast iron is another durable material often used in outdoor furniture. While heavier and more cumbersome than aluminum, cast iron can also be recycled. Its weight makes it particularly valuable in the recycling market.

Metal Swing Sets

Remember that old swing set that the kids have outgrown? Metal swing sets are typically made of steel or aluminum, both of which are recyclable. Taking it apart and recycling the metal can make a big difference.

Old Lawn Mowers

Lawn mowers are primarily made of steel, which is one of the most recycled materials in the world. If your mower has seen better days, consider disassembling it and taking the metal parts to a recycling center.

Broken Grills

That rusty grill taking up space in your backyard can also be recycled. Most grills are made of stainless steel or aluminum. Make sure to remove any non-metal parts before recycling.

Broken AC Units

Air conditioning units may seem like a tricky item to recycle, but they often contain copper, aluminum, and other valuable metals. Contact your local metal recycling center to find out how to properly recycle your old AC unit.

Metal Gates and Fences

Old metal gates and fences can be bulky and hard to dispose of. Fortunately, they are often made of recyclable metals like steel or wrought iron. Breaking them down into manageable pieces will make the recycling process easier.

Leftover Scrap Metal

Whether it’s from a recent DIY project or leftover from home repairs, scrap metal should never be thrown away. Collect all the bits and pieces and take them to a recycling center where they can be processed and reused.

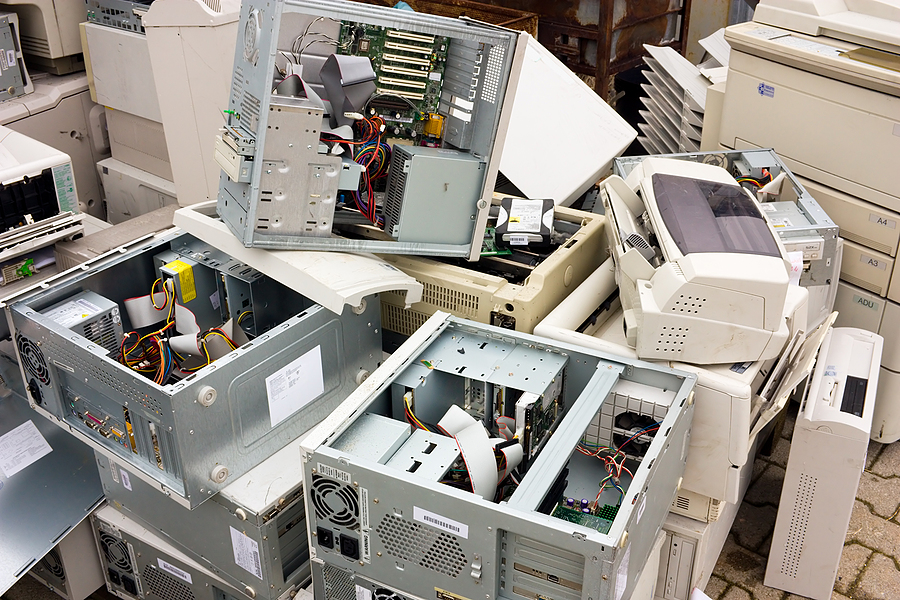

Steps to Prepare Backyard Metal Items for Recycling

Recycling metal from your backyard involves a few preparatory steps to ensure that everything goes smoothly at the recycling center. Here’s how to get started:

- Disassemble Large Items – Large items like swing sets and lawn mowers should be disassembled into smaller, more manageable pieces. This makes it easier to transport and ensures each type of metal is correctly sorted.

- Clean the Metal – Clean your metal items to remove any dirt, grime, or paint. While it doesn’t need to be spotless, removing excess debris can make the recycling process more efficient.

- Sort Different Metals – Different metals have different recycling values. Separate your metals into categories like aluminum, steel, and cast iron. This will help the recycling center process your items more efficiently.

- Safety Measures – Always wear protective gloves and goggles when handling metal items to avoid cuts and injuries. Use appropriate tools like wrenches and pliers to disassemble items safely.

Finding a Local Metal Recycling Center

Once you’ve prepared your metal items, the next step is to find a reliable metal recycling center. Here are some tips for locating and choosing the best facility:

Search Online Directories – Websites like Earth911 and RecyclingCenters.org offer directories of recycling centers across the country. Simply enter your ZIP code to find nearby facilities.

Check Local Regulations – Some areas have specific regulations regarding metal recycling. Make sure the recycling center you choose complies with local laws and accepts the types of metal you’re looking to recycle.

Read Reviews and Get Recommendations – Look for reviews online or ask friends and family for recommendations. A reputable recycling center will have positive feedback and a track record of responsible recycling practices.

Ask About Accepted Items and Payments – Not all recycling centers accept every type of metal. Call ahead to confirm that they accept the items you plan to recycle. Some centers even offer payment for certain metals, so inquire about potential earnings.

Conclusion

Recycling metal items from your backyard is a simple yet effective way to contribute to a more sustainable world. By identifying recyclable items, preparing them correctly, and choosing a reputable recycling center, you can make a significant impact on the environment.

Ready to take action? Start by taking a look around your backyard and gathering any metal items that are ready for recycling. Locate your nearest metal recycling center today and turn your backyard clutter into Eco-friendly treasure. Every small step counts towards a greener future.

Do you want to know where to find the highest-paying scrap metal center in the Indy area? Right here! Contact us at 317-244-0700 for professional and hassle-free scrap metal recycling services in Indianapolis, Indiana. We accept all scrap metal and metal items, including junk cars, appliances, aluminum cans, electronics, automotive parts, and much more. Call now for instant cash!

Related Posts:

Why You Should Upgrade to a Modern Air Conditioner This Summer

How to Do a Scrap Metal Scavenger Hunt That Rewards You With Cash

How to Recycle Junk Appliances in Indianapolis